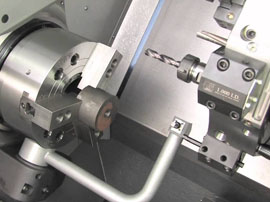

Matrix Precision Engineering has invested in several new Mill / Turn machines with the added benefit of having Live Tooling.

With these additions within our workshop we are now able to complete certain sized parts without the need for secondary set-ups on machining centres. All or most milling aspects of the part can be carried out on the same machine after being turned.

This increases productivity with less set-up times and gives a wider diversity of parts being machined in a single set-up.

Benefits of this machining strategy means a possible reduction in both delivery lead times and machining costs quoted to the customer.

Increased productivity – completing parts with less set-up time

Increased shop capacity – doing more with less floor space

Wider diversity of possible parts can be machined in a single set-up

Possible Live Tooling Operations:

- Axial – Drilling, Milling, Rigid Tapping, Thread-milling

- Radial – Drilling, Milling, Rigid Tapping

- Radial Thread Milling (requires Y-axis)

- C-axis Interpolation

- Cartesian to Polar programming

- Angled Drilling and Tapping

- Angled Thread Milling (requires Y-axis)