Here at Matrix Precision we specialise and have the in-house capability to offer Electrical Discharge Machining. (EDM Wire-Cutting)

In certain circumstances traditional machining methods struggle to meet the demands of highly complex components or difficult to machine material grades.

Our EDM Wire – Cutting capabilities (supported by the latest software & Technology) allow us to support our customer’s ever-growing needs for complex & difficult to machine parts.

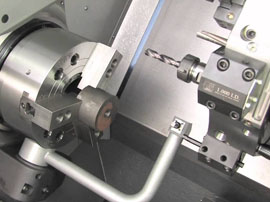

EDM Wire-Cut parts are extremely precise & accurate on any grade of electrically conductive materials. The EDM process creates electrical sparks between the component and the Brass wire of the EDM machine (Brass wire size is just 0.25 mm in diameter). The CNC programmed path of the wire will move along the profile form to be cut & the sparks created remove the material to be cut away.

One of the major benefits of using EDM machining is that it is a non –contact process. This means very minimal clamping forces are required and no (or very minimal) cutting stresses are placed into the component being EDM wire-cut.

Main benefits of EDM Wire-Cutting:

- Ability to machine complex geometry not possible via traditional machining methods.

- Extremely precise & accurate.

- Intricate features, thin walls, narrow slots, tapers, etc. can be cut into parts.

- No tool wear (Brass wire is used)

- Hardened materials can be easily machined.

- Low clamping forces required.

- No stresses placed into the materials from the EDM process.